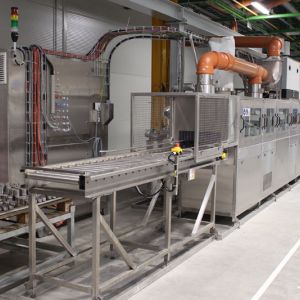

PTM10

Tunnel style degreasing machine with wash, double rinse and hot air drying.

Conveyor machine designed for washing items in loading baskets measuring 545 x 430 x 160 mm. (Although amendments can be made for bespoke measurements). It is divided into two basic parts - soiled and clean.

Sections description

1. Conveyor - entry

At the beginning of the machine is a loading conveyor. This is used to place several loaded baskets on. Which are then automatically transported into the machine at regular intervals.

- 2. Soiled zone

- This is the basic wash cycle which removes most of the debris, via the use of upper and lower spray arms. In later part of this zone the objects are blown with pressurized air knives. The basket is then passed into the clean zone.

- 3. Clean zone

- After entering the clean zone, the basket passes through two rinsing sections with spray arm, primary and secondary. The washed objects are then blown with the use of pressurized air knives and then dried with hot air streams. This whole process is possible thanks to a pressurised blower which is stored in a soundproof box above the machine.

- 4. Conveyor - output

- At the end of the process there is a conveyor that automatically removes the baskets of cleaned and treated items. If the conveyor output is full, the washing process stops automatically until the conveyor belt is cleared.