002-MV500 - special

Specially modified machine with blowing, designed for the washing of pipes, including their inner surfaces.

This machine is based on the basic MV500 version and its exterior is designed almost the same as the basic version. However, the washing area was significantly redesigned. It still contains a support frame, but the frame is specially modified to accommodate a rotary inlet. The inlet supplies two media – washing liquid and air – to the area around which the frame rotates. This enables both the liquid and air to be directed into the interior of the pipe and achieve the desired result.

The washing machine is equipped with an oil trap, a filter basket at the bottom of the washing area and two filter sieves of a different mesh size in the sump. Jets are located both on the sides of the washing area and on the top and bottom.

The machine is transported horizontally on a wooden pallet.

It lies on its right side (viewed from the front).

| Detailed overview of properties | Value |

|---|---|

| Input | 380-415 V |

| Max.current rating | 16,6 A |

| Protection level | IP 54 |

| Electric heater(s) | 1 x 6 kW |

| Temperature setting | 40 - 70° |

| Wash cycle | 0,5 - 5940 min |

| Spray pressure | 3,6 bar |

| Pump flow | 80 l/mi |

| Maximum working height | 1390 mm |

| Basket diameter | 500 mm |

| Maximum load kapacity on tray | 140 kg (35 kg/basket) |

| Solvent capacity | 100 l |

| Working solvent levels | 90 - 100 l |

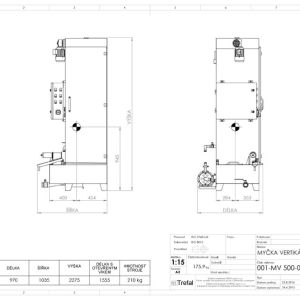

| Dimensions LxWxH | 925 x 1035 x 2275 mm |

| Weight | 220 kg |

| Pump | 1,1 kW |

| Input | 7,5 kW |

| Air Nozzle flow | 6 bar - 49 Nm3/h |